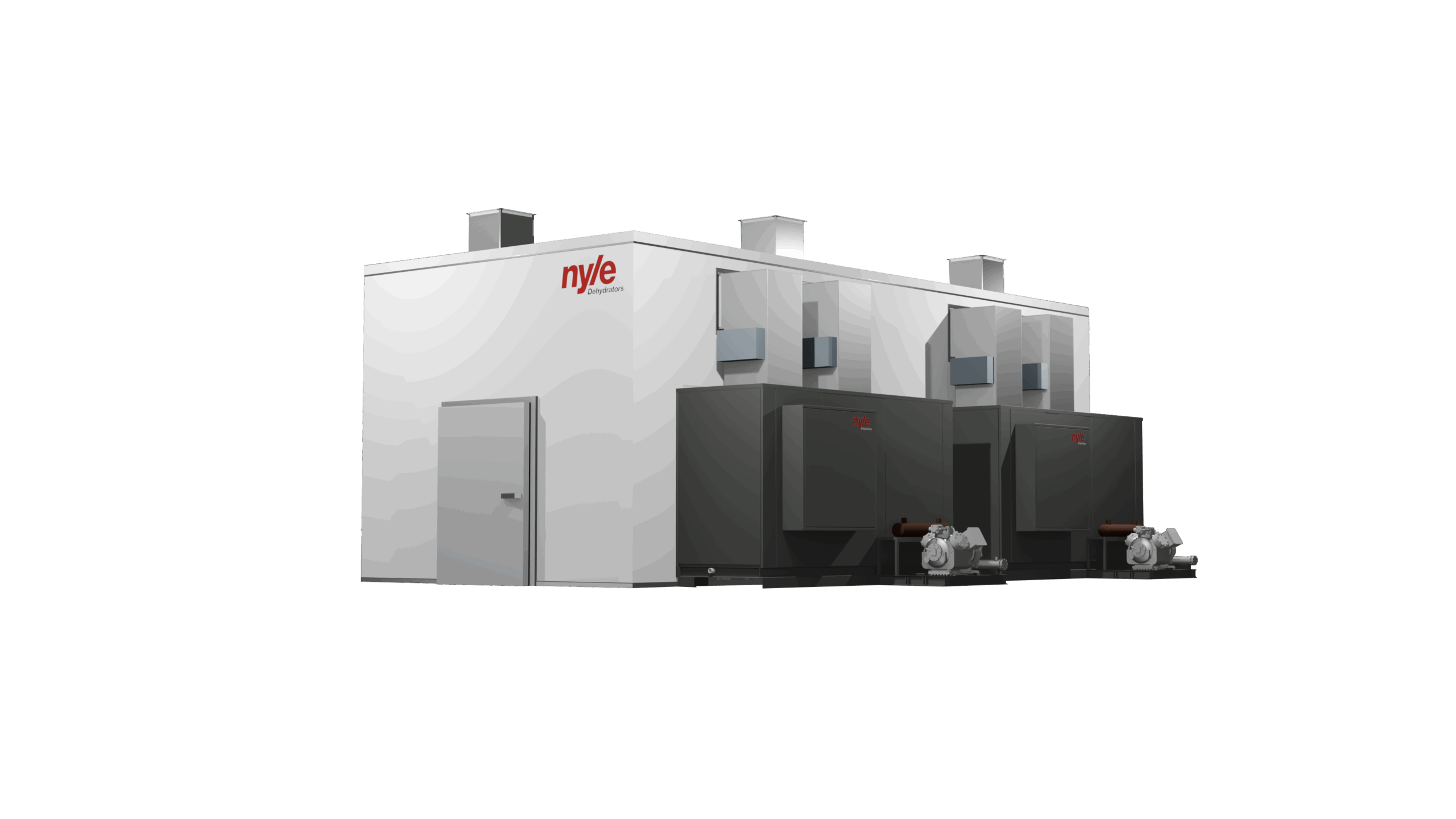

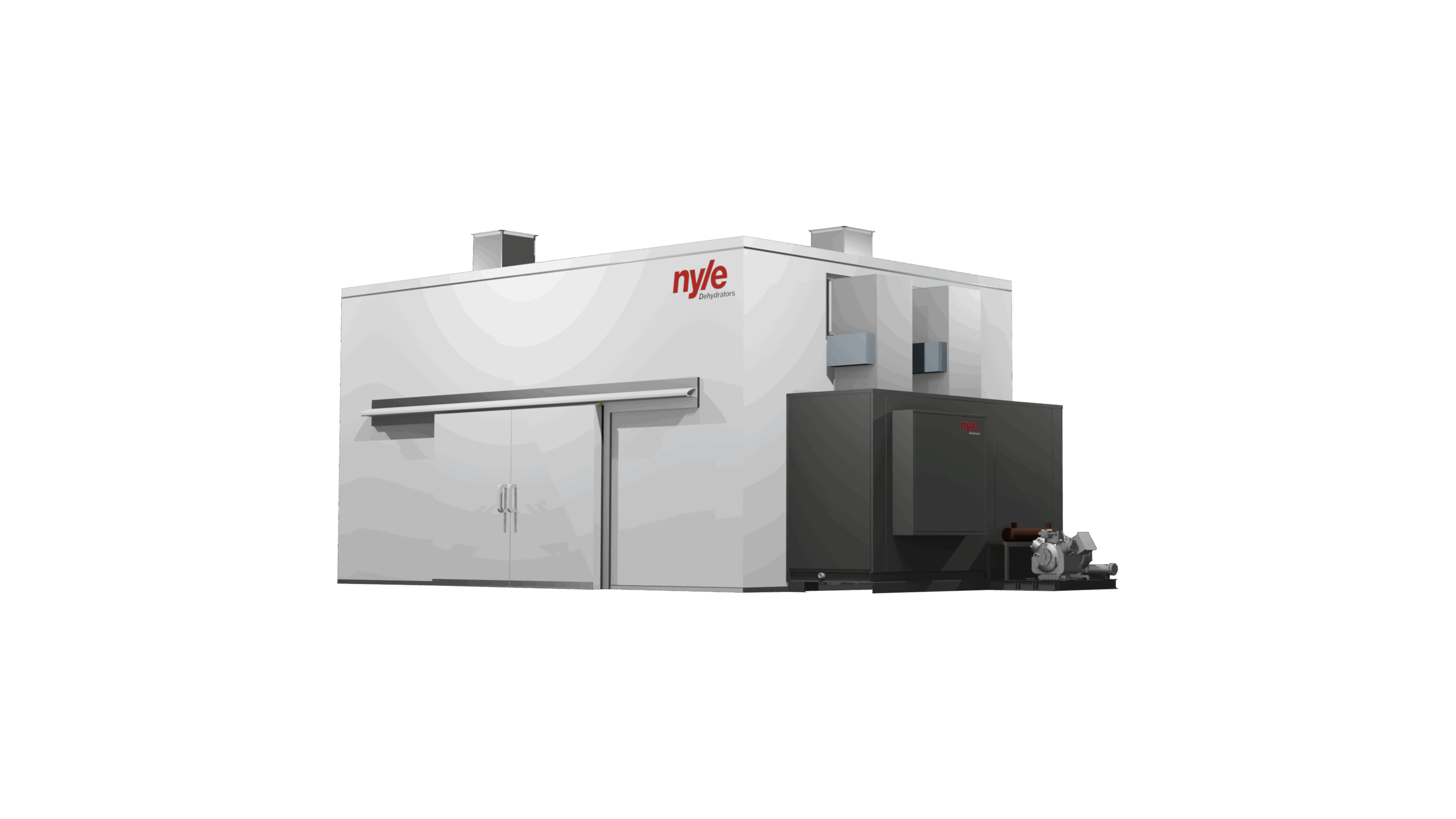

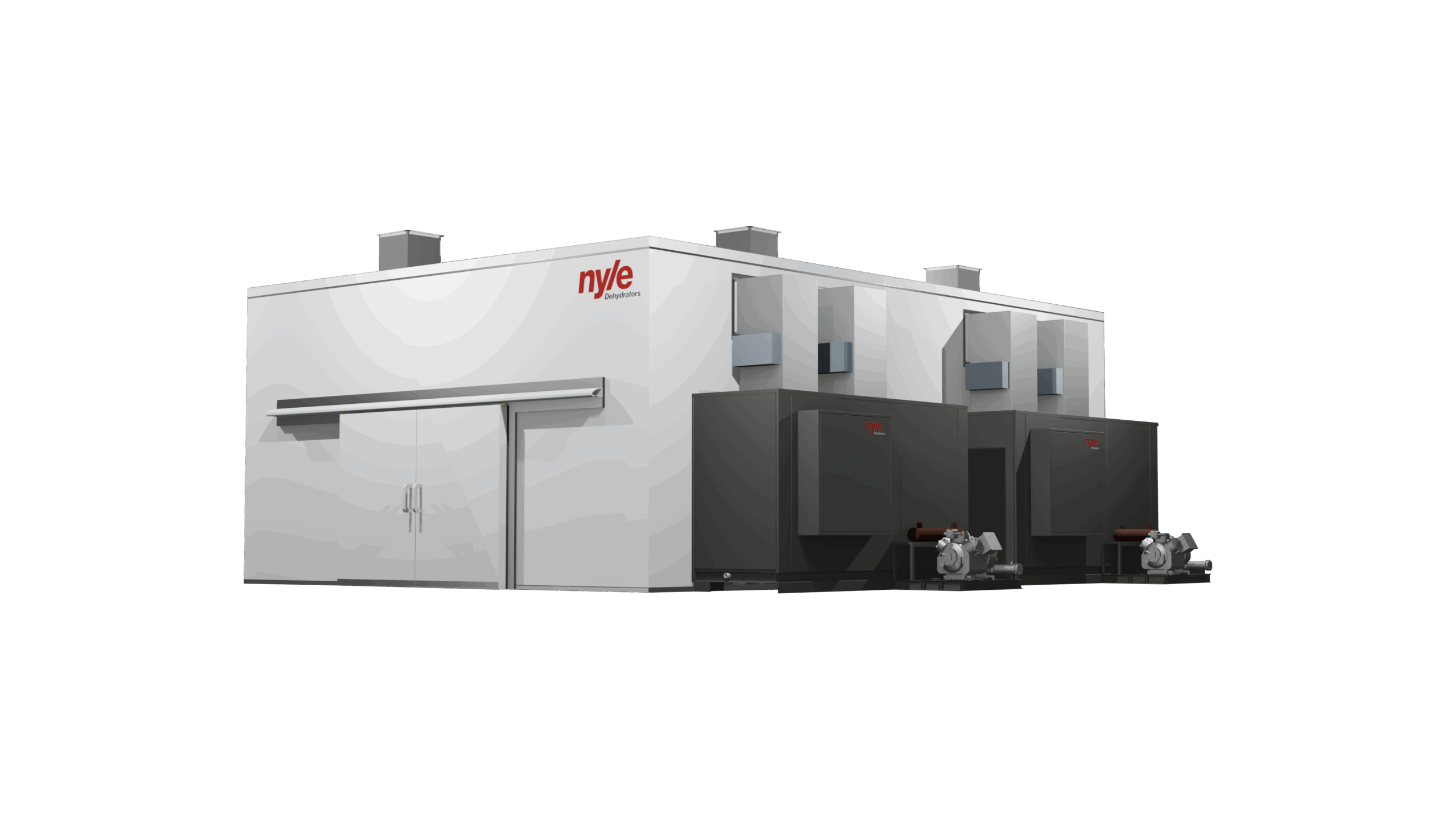

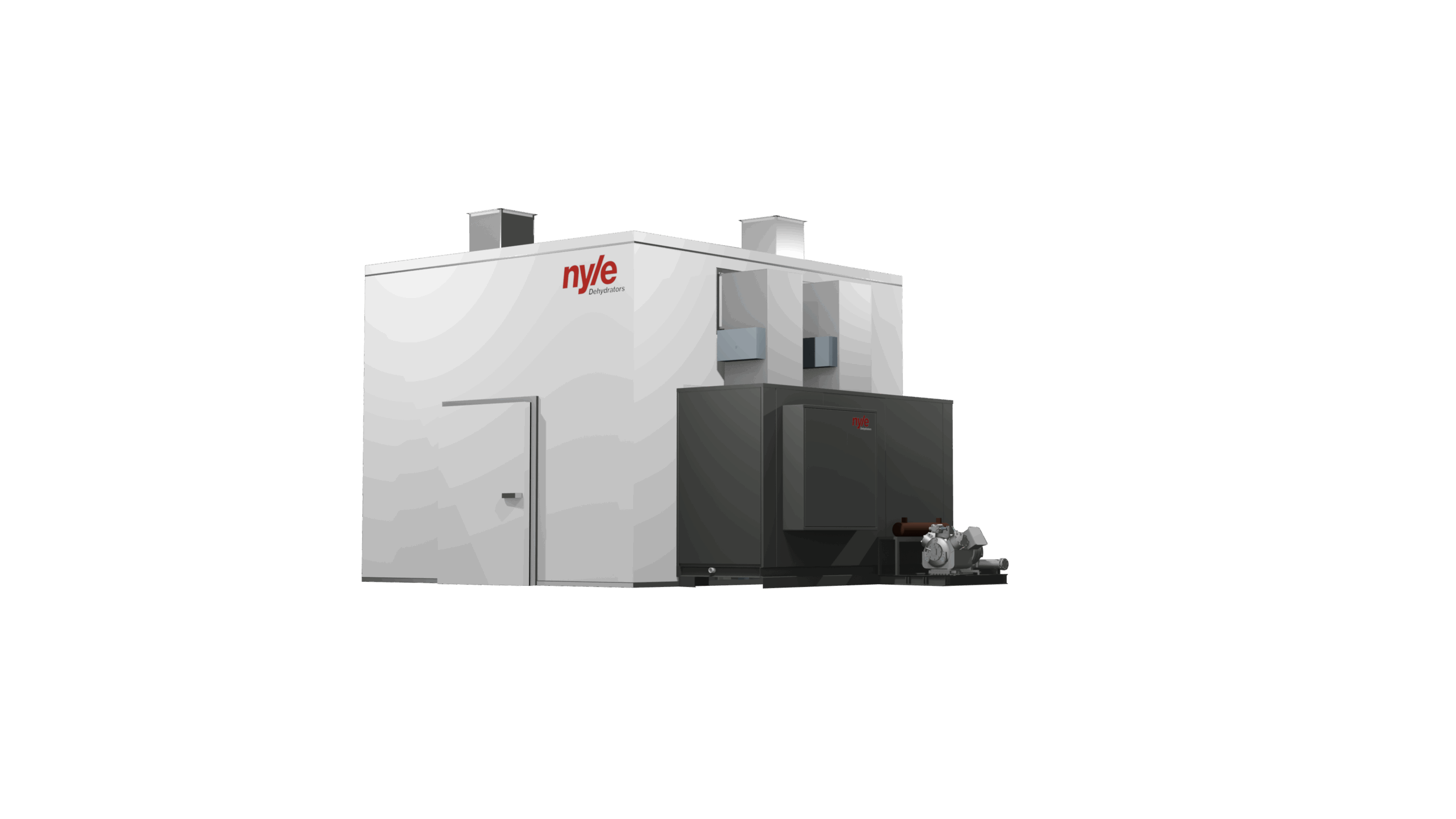

MD110

Scalable Solution for Growing Production Needs

Elevate your dehydration capabilities with the MD110, designed for businesses transitioning to the next level of production. This compact yet powerful unit is perfect for small-scale operations looking to expand output while maintaining efficiency and control. Built with flexibility in mind, the MD110 offers robust performance in a streamlined, single-width design tailored for businesses on the rise.